-

EXHAUST SILENCERS

EXHAUST SILENCERS -

INLET SILENCERS

INLET SILENCERS BAFFLES SILENCERS, SPLITTERS and DUCTS

BAFFLES SILENCERS, SPLITTERS and DUCTS

Standard baffles with glass cloth

Standard baffles with glass cloth

Standard baffles with expanded metal

Standard baffles with expanded metal

Standard baffles with inner resonator

Standard baffles with inner resonator

Acoustic galvanized grille

Acoustic galvanized grille

Double acoustic galvanized grille

Double acoustic galvanized grille

Baffle silencer -10dB(A)

Baffle silencer -10dB(A)

Baffle silencer -14dB(A)

Baffle silencer -14dB(A)

Baffle silencer -19dB(A)

Baffle silencer -19dB(A)

Baffle silencer -25dB(A)

Baffle silencer -25dB(A)

Baffle silencer -30dB(A)

Baffle silencer -30dB(A)

Baffle silencer -39dB(A)

Baffle silencer -39dB(A)

Customized baffles

Customized baffles

Customized ducts

Customized ducts

-

ENCLOSURES, PANELS & DOORS

ENCLOSURES, PANELS & DOORS ACOUSTIC ENCLOSURES

ACOUSTIC ENCLOSURES

-

EXPANSION JOINTS & ANTIVIBRATION

EXPANSION JOINTS & ANTIVIBRATION -

FILTRATION

FILTRATION ABSOLUTE FILTRATION

ABSOLUTE FILTRATION

Glass micro fiber E10

Glass micro fiber E10

Flanged metallic frame E10

Flanged metallic frame E10

HEPA filter aluminium frame H13 to H14

HEPA filter aluminium frame H13 to H14

HEPA filter MDF frame H13 to H14

HEPA filter MDF frame H13 to H14

Pleat filter E10 to H14

Pleat filter E10 to H14

High flow E10 to H14

High flow E10 to H14

High temperature H13-H14

High temperature H13-H14

Multihedral high flow H13

Multihedral high flow H13

Laminar flow H14

Laminar flow H14

Laminar flow H14 gel seal

Laminar flow H14 gel seal

Flanged laminar flow H14

Flanged laminar flow H14

ULPA filter aluminium frame U15

ULPA filter aluminium frame U15

ULPA filter MDF frame U15

ULPA filter MDF frame U15

-

VENTILATION & AIR HANDLING SYSTEMS

VENTILATION & AIR HANDLING SYSTEMS -

FANS

FANS AXIAL FANS

AXIAL FANS

High flow, short housing type

High flow, short housing type

High flow, long housing type

High flow, long housing type

High pressure type

High pressure type

Heavy duty type for genset

Heavy duty type for genset

High flow, high temperature, belt driven type

High flow, high temperature, belt driven type

High flow, wall mounted type

High flow, wall mounted type

Wall mounted type

Wall mounted type

To be built-in duct or wall

To be built-in duct or wall

ATEX High flow, short housing type

ATEX High flow, short housing type

ATEX High flow, long housing type

ATEX High flow, long housing type

Exproof High pressure type

Exproof High pressure type

ATEX Wall mounted type

ATEX Wall mounted type

CENTRIFUGAL FANS

CENTRIFUGAL FANS

Low flow and low pressure, for clean air

Low flow and low pressure, for clean air

Low flow and high pressure, for dusty air

Low flow and high pressure, for dusty air

Centrifugal box fan, galvanized steel

Centrifugal box fan, galvanized steel

Fully dismantabled box fan

Fully dismantabled box fan

High flow, for clean air

High flow, for clean air

High flow, for highly dusty air

High flow, for highly dusty air

High pressure, for laden air

High pressure, for laden air

For heavy dusty air with wood chips

For heavy dusty air with wood chips

ATEX Low flow and low pressure, for clean air

ATEX Low flow and low pressure, for clean air

ATEX Low flow and high pressure, for dusty air

ATEX Low flow and high pressure, for dusty air

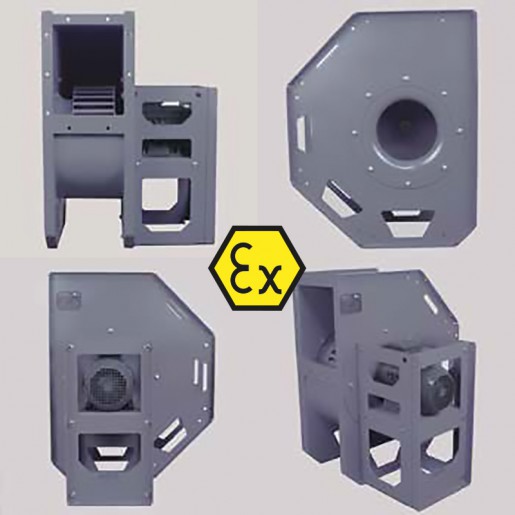

ATEX High flow, for clean air

ATEX High flow, for clean air

ATEX High flow, for highly dusty air

ATEX High flow, for highly dusty air

ATEX High pressure, for laden air

ATEX High pressure, for laden air

-

Acoustics & aeraulics products

for noise & air treatment projects

ATEX centrifugal fan high flow for clean air

Centrifugal fan designed to ensure the extraction of gas, clean air and slightly dusty air in hazardous area, impeller forward curved blades

- Air flow from 2 900 m3/h to 35 000 m3/h

- Pressure from 400 Pa to 2 700 Pa

- ATEX IIB, IIC & 3D

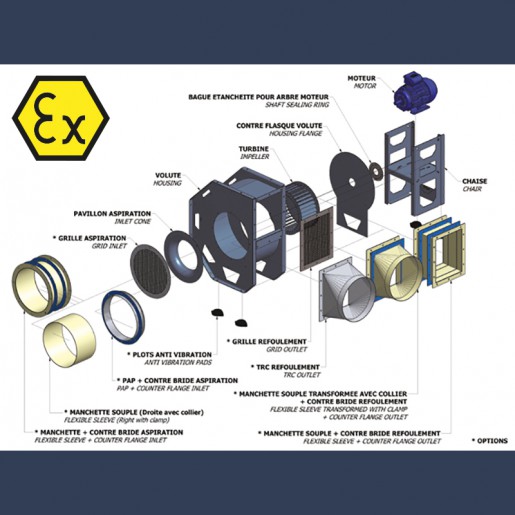

Description

Centrifugal fan ATEX model for gas and air extraction in explosive area

Impeller backward curved blades for clean and slightly dusty air

Fabrication

- Housing painted carbon steel

- Available in Stainless steel in Atex 3D version

- GRID Inlet and outlet

- MOTOR CE Ex II2 G T* IIB or CE Ex II2 G T* IIC, for area 1 (Gb) or 2 (Gc) (for ATEX model)

CE Ex II2 D T* IIIB or CE Ex II2D T* IIIC, for area 21(Db) or 22 (Dc) (for ATEX model) *following motor plate

- Flexible antistatic sleeve (option)

- Impeller Forward-curved blades in carbon painted steel

Conditions

- Ambient temperature between -20°C and +40°C (unless otherwise paid to the motor nameplate)

- Fluid temperature between -20°C and +80°C

Standards

- Our ATEX fans meet the new ATEX Directive 2104/34/EU and to the standards EN 13463-1 and EN 14986

- In accordance with machine directive 2006/42/EC and Directive 2009/125/EC

- Safety in accordance with EN ISO 12499

- Turbine balanced ISO 1940 (standard class G6.3)

- Each fan tested in operation with vibration control according to ISO 14694

- All performance values are given for 15°C, for other data please contact us

Product Details

Data sheet

- Material

- Painted carbon steel

- Impeller

- forward-curved blades

- Air quality

- slightly dusty

Attachments

Download

Centrifugal fan PAS dimensions

External dimensions & exploded view

Download (199.07k)Centrifugal fan PAS curves

Flow - pressure curves

Download (114.22k)Additional products

Centrifugal fan designed to ensure the extraction of gas, clean air and slightly dusty air in hazardous area, impeller forward curved blades

- Air flow from 2 900 m3/h to 35 000 m3/h

- Pressure from 400 Pa to 2 700 Pa

- ATEX IIB, IIC & 3D

DIESEL and GAS ENGINES SILENCERS

DIESEL and GAS ENGINES SILENCERS -25 dB(A)

-25 dB(A) -25 dB(A) SS304L

-25 dB(A) SS304L -30 dB(A) radial

-30 dB(A) radial -30 dB(A) Ship engine type

-30 dB(A) Ship engine type -35 dB(A) Ship engine type

-35 dB(A) Ship engine type -40 dB(A) Container type

-40 dB(A) Container type -50 dB(A)

-50 dB(A) TURBINES SILENCERS

TURBINES SILENCERS Gas turbine cylindrical exhaust silencer

Gas turbine cylindrical exhaust silencer Gas turbine baffles silencer

Gas turbine baffles silencer INDUSTRIAL SILENCERS

INDUSTRIAL SILENCERS Cylindrical type

Cylindrical type Baffles type

Baffles type Discharge type 15bars

Discharge type 15bars ADDITIONAL EQUIPMENT

ADDITIONAL EQUIPMENT Acoustic baffles

Acoustic baffles Insulated ducts

Insulated ducts  Heavy duty ducts

Heavy duty ducts  DIESEL and GAS ENGINE SILENCERS

DIESEL and GAS ENGINE SILENCERS -25dB(A)

-25dB(A) FANS and HVAC INLET SILENCERS

FANS and HVAC INLET SILENCERS Ventilation attenuator

Ventilation attenuator Blower type -10dB(A)

Blower type -10dB(A) Fan type -18dB(A)

Fan type -18dB(A) Fan type -35dB(A)

Fan type -35dB(A) HVAC type -20dB(A)

HVAC type -20dB(A) TURBINE INTAKE SILENCERS

TURBINE INTAKE SILENCERS Filter type -20dB(A)

Filter type -20dB(A) INDUSTRIAL PANELS

INDUSTRIAL PANELS Acoustic & fireproof steel sheets panels

Acoustic & fireproof steel sheets panels Acoustic perforated sheet panels

Acoustic perforated sheet panels Modular panels for noise insulation

Modular panels for noise insulation Modular panels for noise absorption

Modular panels for noise absorption Heavy duty expanded metal panels

Heavy duty expanded metal panels Soundproof enclosure for fan

Soundproof enclosure for fan BUILDING PANELS

BUILDING PANELS Wall insulation panels

Wall insulation panels Ceiling insulation panels

Ceiling insulation panels Floor insulation panels

Floor insulation panels ARCHITECTURAL PANELS

ARCHITECTURAL PANELS Square MDF wood effect

Square MDF wood effect Customizable wood-fabric finish

Customizable wood-fabric finish DOORS

DOORS Multipurpose steel door

Multipurpose steel door Insulated steel door

Insulated steel door Fire door class EI2 60

Fire door class EI2 60 Heavy duty fire door class EI2 60

Heavy duty fire door class EI2 60 Heavy duty fire door class EI2 120

Heavy duty fire door class EI2 120 Acoustic door Rw 30dB

Acoustic door Rw 30dB Acoustic door Rw 36dB

Acoustic door Rw 36dB METAL EXPANSION JOINTS

METAL EXPANSION JOINTS All stainless steel

All stainless steel Weld end

Weld end Fixed flanged

Fixed flanged Floating flanged

Floating flanged Axial type

Axial type Lateral type

Lateral type ANTIVIBRATION DEVICES

ANTIVIBRATION DEVICES 1 spring hanger

1 spring hanger 1 spring support

1 spring support 1 spring support

1 spring support 2 springs support

2 springs support 4 springs support

4 springs support 1 spring prestressed compact box

1 spring prestressed compact box 1 spring prestressed box

1 spring prestressed box FABRIC EXPANSION JOINTS

FABRIC EXPANSION JOINTS Belt type circular

Belt type circular Belt type rectangular

Belt type rectangular Belt type with bolster circular

Belt type with bolster circular Belt type with bolster rectangular

Belt type with bolster rectangular Flange type circular

Flange type circular Flange type rectangular

Flange type rectangular RUBBER EXPANSION JOINTS

RUBBER EXPANSION JOINTS One sphere metal flanges

One sphere metal flanges Double sphere metal flanges

Double sphere metal flanges With threaded unions

With threaded unions With inner PTFE liner

With inner PTFE liner Full integrated rubber flanges

Full integrated rubber flanges Integrated flanges

Integrated flanges PRIMARY FILTRATION

PRIMARY FILTRATION Synthetic media G2-G3-G4

Synthetic media G2-G3-G4 Glass fiber media G3-G4

Glass fiber media G3-G4 Paper media-paint stop

Paper media-paint stop Polyester cells G3-G4

Polyester cells G3-G4 Metal cells G2 200°C

Metal cells G2 200°C Glass fiber cells G3

Glass fiber cells G3 Glass fiber cells G4 300°C

Glass fiber cells G4 300°C Polyester cells G4 high flow

Polyester cells G4 high flow Synthetic bags G3-G4

Synthetic bags G3-G4 Filter housing

Filter housing FINE FILTRATION

FINE FILTRATION Synthetic media M5

Synthetic media M5 Glass fiber cells M5 to F9 300°C

Glass fiber cells M5 to F9 300°C Glass micro fiber cells M6 to F9

Glass micro fiber cells M6 to F9 Synthetic bags M5-M6

Synthetic bags M5-M6 Synthetic micro bags M6 to F8

Synthetic micro bags M6 to F8 Synthetic nano bags M6 to F9

Synthetic nano bags M6 to F9 Glass micro fiber bags M5 to F9

Glass micro fiber bags M5 to F9 Compact rigid bags M6-F9

Compact rigid bags M6-F9 Turbogas bags M6-F9

Turbogas bags M6-F9 Energy saving bags F7-F9

Energy saving bags F7-F9 PURIFICATION

PURIFICATION Bulk activated carbon

Bulk activated carbon Activated carbon media G3

Activated carbon media G3 Activated carbon filter cells

Activated carbon filter cells Activated carbon cells

Activated carbon cells Multihedral activated carbon cells

Multihedral activated carbon cells Activated carbon box

Activated carbon box Activated carbon filters set

Activated carbon filters set Activated carbon plates-cartridges set

Activated carbon plates-cartridges set Single activated carbon cartridge

Single activated carbon cartridge Activated carbon rigid bags

Activated carbon rigid bags DISTRIBUTION RECTANGULAR NETWORKS

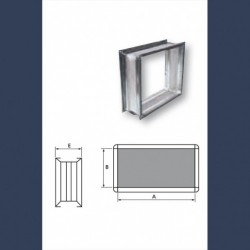

DISTRIBUTION RECTANGULAR NETWORKS Straight duct

Straight duct Elbow shape duct

Elbow shape duct 3 ways duct

3 ways duct Offset duct

Offset duct Transition duct

Transition duct Transformation duct

Transformation duct Connection flexible sleeve

Connection flexible sleeve DISTRIBUTION CIRCULAR NETWORKS

DISTRIBUTION CIRCULAR NETWORKS Straight duct

Straight duct Elbow shape duct

Elbow shape duct T-shaped duct

T-shaped duct Male-female connector

Male-female connector Reduction duct

Reduction duct Horizontal connector

Horizontal connector Flexible sleeve kit

Flexible sleeve kit Locking plug

Locking plug Fixing collar

Fixing collar Beveled vent

Beveled vent Roof hat

Roof hat REGULATION

REGULATION Rectangular Damper

Rectangular Damper Circular Damper

Circular Damper Customizable airflow damper

Customizable airflow damper Vacuum shutters

Vacuum shutters Overpressure shutters

Overpressure shutters Reversible shutters

Reversible shutters DIFFUSION

DIFFUSION Galvanized grille 30

Galvanized grille 30 Galvanized grille 50

Galvanized grille 50 Galvanized grille 75

Galvanized grille 75 Galvanized louvre systems

Galvanized louvre systems Aluminium grille 30

Aluminium grille 30 Aluminium grille 50

Aluminium grille 50 Aluminium grille 75

Aluminium grille 75 Aluminium louvre systems

Aluminium louvre systems JET FANS and SMOKE EXTRACTORS

JET FANS and SMOKE EXTRACTORS Axial jet fan 300°C 2H

Axial jet fan 300°C 2H Centrifugal jet fan 300°C 2H

Centrifugal jet fan 300°C 2H Smoke extractor 300°C 2H

Smoke extractor 300°C 2H Axial jet fan 400°C 2H

Axial jet fan 400°C 2H Centrifugal jet fan 400°C 2H

Centrifugal jet fan 400°C 2H Smoke extractor 400°C 2H

Smoke extractor 400°C 2H TURRETS

TURRETS Compact roof turret

Compact roof turret High flow multifunction roof turret

High flow multifunction roof turret Axial turret for light extraction

Axial turret for light extraction Centrifugal turret, high flow, high pressure for dusty air

Centrifugal turret, high flow, high pressure for dusty air ATEX Axial turret for light extraction

ATEX Axial turret for light extraction ATEX Centrifugal turret, high flow, high pressure for dusty air

ATEX Centrifugal turret, high flow, high pressure for dusty air